Mitee Bite Clamps: Maximizing Efficiency in Precision Workholding Solutions

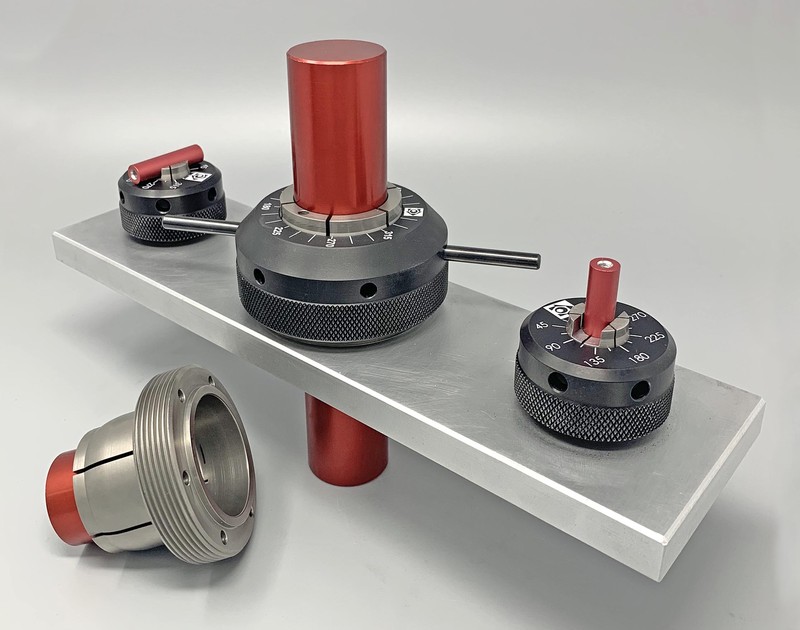

Precision in manufacturing is crucial, and Mitee-Bite Clamps bring unparalleled efficiency to the table. With their OK-Vise® Wedge Clamps or robust Pitbull® series, these tools elevate workpieces for seamless mill/drill operations while keeping a low profile — key in space-sensitive tasks. The newly launched Heavy Duty™ T-Slot Clamp stands out by delivering over 20,000 pounds of clamping force.

Whether it’s high-pressure needs or diverse configurations you seek, Mitee-Bite offers solutions that ensure your projects meet exacting standards with ease and reliability. Plus, they’re now available through the innovative TITANS of CNC Academy kits.

Explore Mitee Bite Clamps Innovation

Mitee Bite’s clamping solutions, like their DK model OK-Vise® Wedge Clamps and hefty Pitbull® Clamps, are revolutionizing the machining world. For instance, when you need to hold your workpiece aloft for mill or drill-through tasks, these tools come in handy by applying immense pressure onto parts with precision. The Heavy Duty™ T-Slot Clamp is a game-changer that can exert over 20,000 pounds of force.

Because they fit on a common base in multiple configurations, offering abundant holding power—more than usually necessary—you’ll ensure efficiency and accuracy during every operation. You’ll enjoy seamless integration into any setup where robustness meets versatility. Just take a look at Suncoast Precision Tools for examples of Mitee Bite products that maintain high performance across diverse applications.

Enhance Workholding with Precision Solutions

Elevate your production with Mitee-Bite clamps, designed to skyrocket efficiency. Imagine cutting at a breath-taking 14,000 rpm and feeding a robust 250 inches per minute (ipm). Now, compared to the sluggish pace of just 100 ipm when using standard vises, there is no contest.

Using these clamps not only means “flying through material” but also precision handling of intricate bicycle components like aluminum pedals without slipping—even with minimal grip surfaces as slight as 090 inches. Moreover, implementing custom fixture plates matched in size to tombstone faces optimizes compatibility and utilization. Precise dowel pins anchor the setup securely, while bolted palletized tombstones ensure unwavering stability during high-speed machining operations.

This ingenious system permits rapid exchange between tasks—an air tool swiftly tightens or loosens clamp cap screws—minimizing downtime and propelling productivity forward. This fusion of speed and steadfastness transforms workholding into an art form where every second saved is profit earned.

Suncoast Tools Meets Mitee Bite Efficiency

As you look into machining, Suncoast Precision Tools has teamed up with Mitee-Bite’s workholding prowess to amplify outcome efficiencies. The transformative Heavy Duty VersaGrip™ clamps embody this synergy—robust enough for tougher materials and versatile in gripping diverse shapes securely. These innovative tools offer both standard and elevated configurations through the Original VersaGrip or tailored pucks sitting within the Versa pockets.

Furthermore, Mitee-Bite’s strategic offerings extend to education via TITANS of CNC Academy Kits—enabling future machinists to grasp fixturing proficiency using various clamps from their product range. Truly empowering workshops lie ahead as these smart solutions foster a new caliber of precision and productivity across industries—from aerospace giants down to local machine shops alike.

You can boost your workholding efficiency with Mitee Bite clamps. They offer strong hold and precision for all types of projects. These tools are known for saving time on setups and increasing machine run times, so productivity goes up without sacrificing quality.

Whether you’re doing intricate machining or robust milling, reliable grip is key—Mitee Bite delivers this every time! Perfect your craft by including them in your toolbox; let Suncoast Precision Tools help guide the way to more efficient operations today.