Efficient Automation in Modern Bottle-Filling Machine Systems

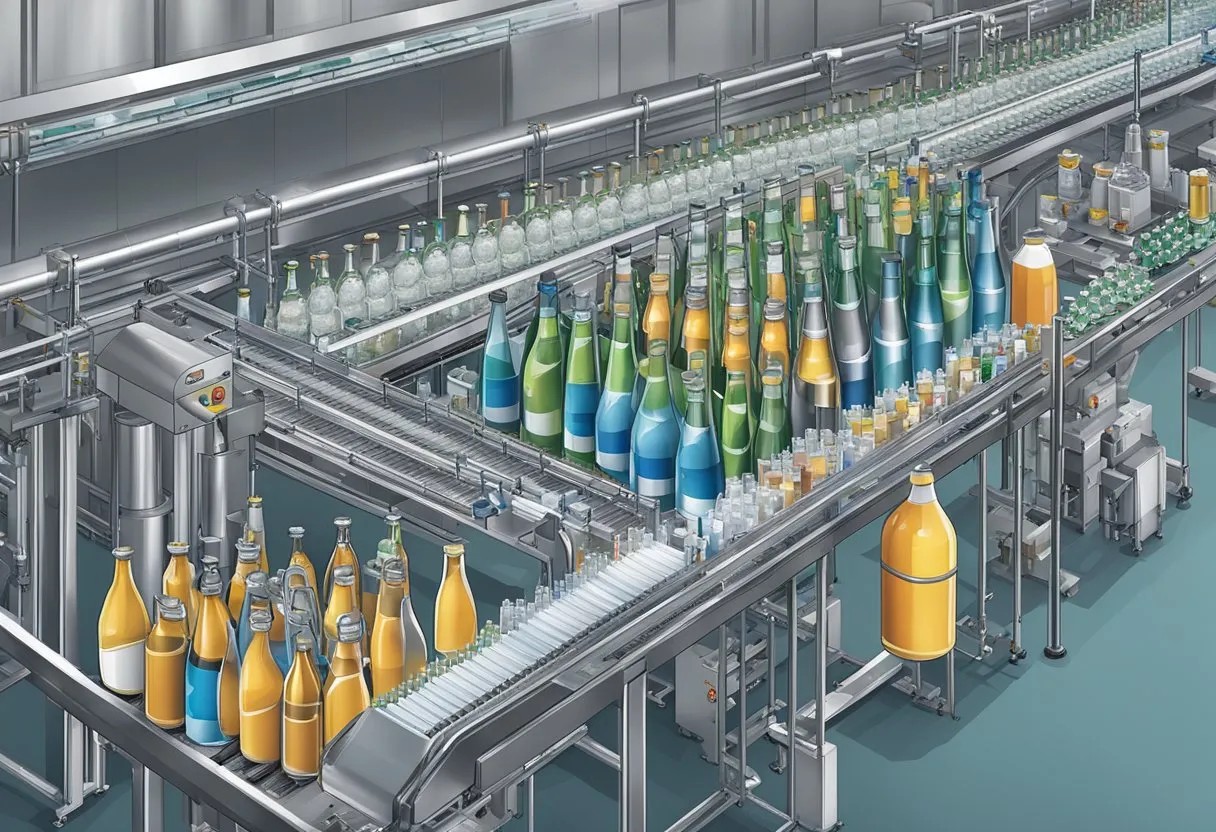

Bottling line machinery hums with a newfound intensity, churning out filled containers at an unprecedented rate thanks to automation’s sudden surge. Modern bottle-filling machines and their automated processes stand at the forefront.

From day one, these advanced systems pledge to reduce lag time and revamp the pace of production, effortlessly integrating with existing workflows. With precision timing, machines fine-tune every bottle’s fill level, thereby streamlining the entire production process by folding, capping, and labeling into a single, sleek operation.

Modern problem-solvers depend on three critical factors: pinpoint accuracy, seamless integration, and breakneck speed—this powerful trifecta drives meaningful progress. Let’s not forget that these machines do more than just fill bottles quickly.

Maximizing Precision with Automated Bottle Fillers

Automated bottle fillers are game-changers for businesses in the food and beverage industries. You’ll see a dramatic leap in efficiency with these machines, which can handle thousands of bottles every hour without needing a break. This means your production lines keep moving fast, meeting demand effortlessly.

Check out bottle filler equipment automation for leading solutions that make manual labor almost obsolete. Precision is non-negotiable in bottling operations. Here’s where automated systems shine by ensuring each PET bottle gets filled just right.

Neither too much nor too little. Sensors and controls work tirelessly to maintain this precision across all bottles, guaranteeing the quality that builds customer trust. Initially, setting up an automatic bottle-filling machine might seem costly, but consider the savings over time.

Labor costs drop as you need fewer hands on deck; product waste diminishes thanks to reduced human error; overall productivity sees a surge. All are contributing to significant operational cost cuts while boosting profitability amid stiff market competition. Furthermore, maintaining high hygiene standards is simpler with automated systems made from easy-to-clean materials like stainless steel, and minimized human contact ensures safety and compliance with health regulations.

A must-have feature when dealing with consumable liquids. With their versatility at adjusting speeds or handling various liquids and bottle sizes

Seamless Integration of Modern Filling Systems

- Types of Automated Filling Machines: Choosing the right automated filling machine involves understanding your product needs. Volumetric fillers ensure precise portioning for consistent quality, which is valuable in packaged foods like ready meals. Whether you’re handling liquids or dry goods determines if a liquid filler or powder filler best meets your requirements.

- Key Benefits of Automation: Investing in an automated filling system brings significant efficiency gains and accuracy improvements to food packaging operations. These systems can process thousands of containers per hour with minimal waste, promoting both cost savings and consumer trust through reliable product quality.

- Modern Trends and Sustainability: The latest advancements integrate IoT for smarter production management while emphasizing sustainability, which is important for eco-conscious brands aiming to use recyclable materials without sacrificing operational speed or hygiene standards essential in the food industry.

Choosing the right bottle-filling machine, like the GlobalTek Fill-It 6 Head with precision nozzles and advanced PLC control, isn’t just about speed. It’s ensuring every drop counts towards greater efficiency and less waste in your production line. With a sturdy stainless steel frame and powerful centrifugal pump, this system handles high-demand environments effortlessly.

Investing in such automation transforms your operation by improving accuracy, consistency, and, ultimately, customer satisfaction. Remember, picking a top-notch filler isn’t merely an upgrade. It’s a wise step into future-proofing your business for tomorrow’s challenges.